| Have thoughts or feedback? Anything I missed this week? Email me at bsutherland7@bloomberg.net. To get Industrial Strength delivered directly to your inbox, sign up here. Most large manufacturers insist that tariffs won’t blow a hole through their bottom line, but costs can’t jump by hundreds of millions of dollars across the industrial supply chain without something breaking. Industrial companies have flagged a broad range of cost increases linked to tariffs, from $1.7 billion at power-tool maker Stanley Black & Decker Inc. to $850 million at 3M Co., $500 million for Honeywell International Inc. and GE Aerospace to less than $200 million at pool pump-maker Pentair Plc and Ingersoll Rand Inc. Regardless of the overall headline number, nearly every manufacturer outside of the automotive industry says they can fully offset the impact of President Donald Trump’s sweeping import taxes through supply-chain tweaks and price increases. Stanley Black & Decker, arguably the most affected by tariffs among general manufacturers, expects to earn about 15% less per share this year than it did before Trump unveiled his sweeping levies. For context, however, that would still imply earnings are up on a year-over-year basis. With the vast majority of industrial companies expecting a zero dollar net impact from broad-based import taxes, “one wonders why tariff increases don't occur annually into perpetuity,” Barclays Plc analyst Julian Mitchell wrote in a note. Read more: Manufacturers Can't Avoid Consumer Slowdown Part of the reason for the optimism is that industrial demand has held up fairly well so far this year. The risk is that at least some of those new equipment purchases are happening because of the tariff chaos, not in spite of it, as companies seek to stockpile inventory. Import data released this week by the Department of Commerce show double-digit year-over-year increases in March for shipments of air conditioner and heater components, electrical equipment, pool products and power tools, according to an analysis by Mitchell. This suggests that there was indeed a push to amass goods ahead of tariffs — despite across-the-board vows from industrial companies that there has been minimal evidence of such buying patterns propping up their results, he said. The stockpiling tees up the risk of an inventory hangover in the back half of the year, much like the one that followed in the wake of the Covid supply chain disruptions. It’s worth remembering that back then most companies said there was no indication their customers were over-ordering, either.

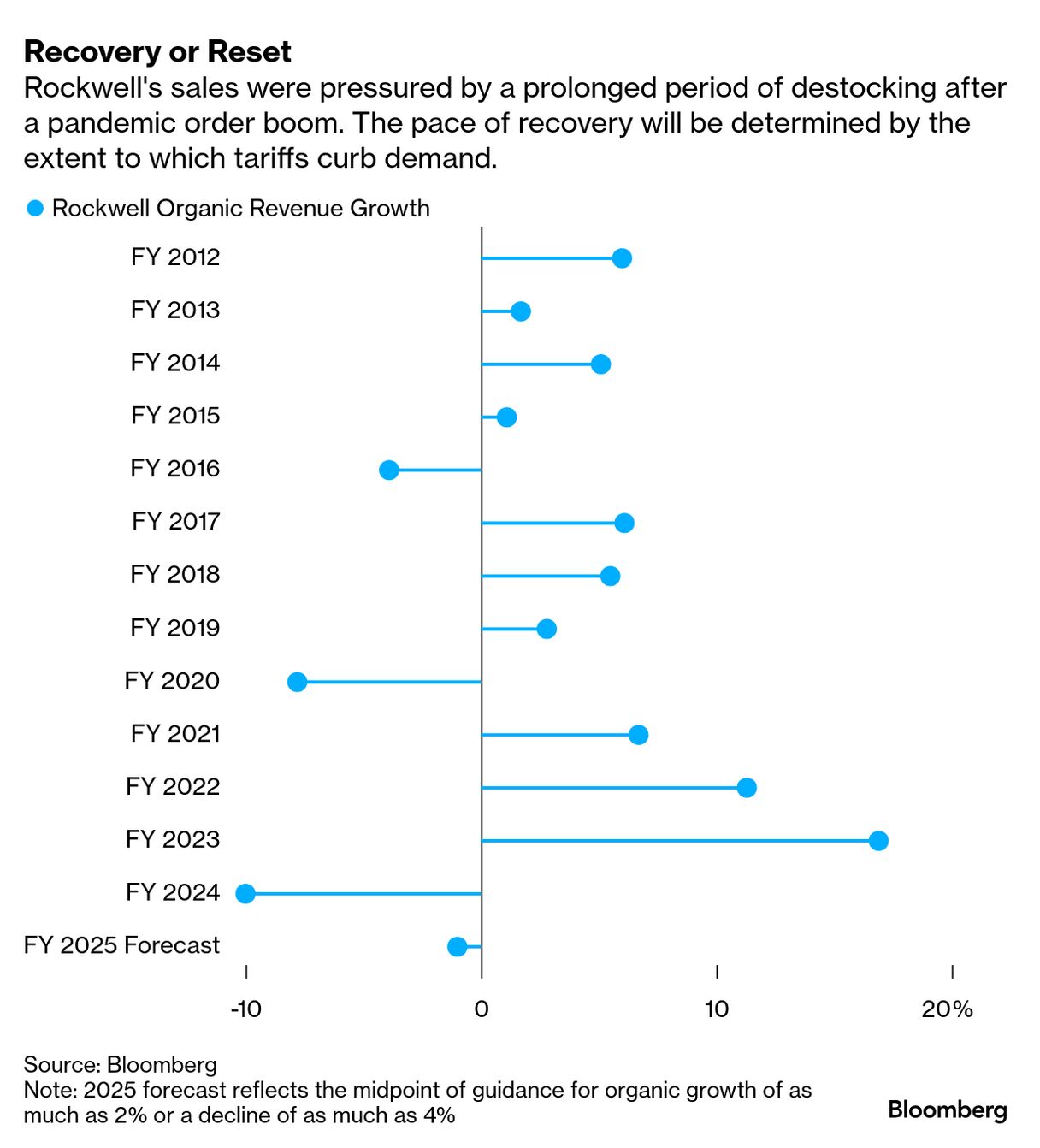

Much like how people tend not to buy more bottles of shampoo when they already have 10 sitting in a closet, industrial companies also tend to whittle down their existing supplies before purchasing more equipment — especially if demand starts to wobble or isn’t as robust as anticipated when they ordered all this stuff. What started as pockets of pressure in consumer goods in 2022 soon spread to chemicals, home generators, roofing shingles, life sciences, residential air conditioners and heating systems, restaurant-grade kitchen supplies, fire and security products, factory automation technologies and electrical equipment, among other things. Read more: For Industrials, Promised New Era Is On Hold The Institute for Supply Management’s gauge of US manufacturing activity entered contraction territory in the fall of 2022 and didn’t bounce back until January of this year — the longest ever slump for the benchmark. Manufacturers say they’re taking steps to guard against another destocking recession. Pentair and Rockwell Automation Inc. are both capping customer orders to avoid a buildup of shadow inventory. But it can be difficult to ascertain the appropriate pace of activity in periods of volatility. Demand was just starting to perk back up across the industrial economy before Trump’s shock tariff announcement in April, so there should be a snapback in orders if that continues. But there is also growing evidence that companies are pulling back on spending as they wait to see what the ultimate playing field will look like for international trade. The Trump administration this week announced a bare-bones framework agreement with the UK that included better market access and a faster customs process for American goods as well as some relief for the UK on tariffs. Negotiations with China are also set to begin in the coming days, with Trump touting the prospect of “substantive” progress that could help reset what has effectively become a trade embargo between the two countries. Read more: Factory Recovery Looms And So Do Tariffs Wolfe Research’s capital spending expectations index fell in April to the lowest level since 2020, according to analyst Nigel Coe. “Notably, we are seeing a clear bias towards inventory build — related to tariffs — and an equally profound outlook for de-stocking during” the second half of 2025, he wrote in a note this week. “We are encouraged by the less anarchic policy positions coming out of the White House. But there remains much to be resolved, and it is too early to accurately gauge the extent of demand destruction from all the uncertainty.” Rockwell Automation has seen some projects get delayed because of uncertainty about how tariffs would inflate costs, particularly in the automotive industry which is trying to figure out how to rewire a highly globalized supply chain designed for the old economic order. “In the current environment, which with so much uncertainty about their cost, they're being particularly cautious,” Rockwell Chief Executive Officer Blake Moret said in an interview. Some state-owned Chinese enterprises outright canceled orders because of government pressure to not work with US companies, he said. Amid concerns that the tariff standoff might permanently impair US companies’ competitiveness in China, “I will say, I'm not feeling particularly bad about having less than 4% of my revenue coming from China right now,” Moret said.

Other projects were postponed because of concerns about higher-for-longer interest rates and challenges raising funds through the public markets or venture capital, while lower prices for oil and other commodities have undermined the return calculus for certain investments in the energy and mining sectors, Moret said. To that end, Diamondback Energy Inc., the largest independent oil producer in the Permian Basin, this week said production has likely peaked in America’s shale fields, warning of dwindling crew and rig counts across the industry this year and cutting its own production forecast. Steelmaker Cleveland-Cliffs Inc., meanwhile, announced plans to fully or partially idle six facilities to help cut costs and stem widening losses.  But in other cases, companies just want to “make sure that they've got all their ducks in a row” and are taking extra time to review contract terms to protect against disruptions and surprises, Moret of Rockwell said. Some projects that were delayed in the last quarter started to move forward again in April, a sign that the pullback may be just temporary, he said. Still, even as Rockwell raised its full-year earnings guidance, the company kept its forecast for as much as a 4% decline in sales this year absent currency swings and M&A to reflect uncertainty about demand and the timing of spending by customers. “A lot of people worry that we may go off the track,” said Nicholas Pinchuk, CEO of Snap-on Inc., which makes tools for auto mechanics. “People of many stripes, particularly in the business sector, believe we're going to the right place” and support the Trump administration’s overarching goal of bolstering US manufacturing, he said in an interview. “What they worry about is the administration doesn't know how to get it done," he said. "It doesn't look that good, you know? If you look at it, boy, it seems like things are going back and forth. It's why, in general, companies are sitting back and saying, 'Well, I've got to keep my powder dry and wait to see how this all plays out.'"

Snap-on itself primarily makes its US-bound products domestically so it can manage the impact of tariffs with minimal disruption to its supply chain, Pinchuk said. But the uncertainty is still weighing on its results: core sales for its tools division fell 6.8% in the most recent quarter as mechanics pulled back on purchases of bigger ticket items.  | | | “We know where everything comes from.” — Vicente Reynal, CEO of Ingersoll Rand Reynal made the comments in an interview after the compressor manufacturer reported its first-quarter results. Trump’s first trade war and the disruptions of the pandemic forced manufacturing executives to become intimately familiar with every logistical detail behind the production of their wares — a knowledge level that was previously reserved for an out-of-the-spotlight supply chain team toiling away in the background. Supply chains have always been important but in recent years, they have become existential and that will work to manufacturers’ advantage as they navigate this latest barrage of tariffs. In Ingersoll’s case, the company has set up a tariff war room that’s charged with measuring how the levies are impacting business activity and analyzing every possible way to “maximize how the flow of the supply chain works,” Reynal said. That includes not just Ingersoll’s finished products, which are primarily made in the region in which they’re sold. But also the components that go into the parts it buys from suppliers. In some cases, Ingersoll’s suppliers may already have alternate facilities across the world where they could shift production out of China to lessen the blow from tariffs, Reynal said. Still, the company is also preparing for price increases from US-based parts makers who will need to offset the cost of tariffs on components that they import. That knock-on effect is included in Ingersoll’s estimate of $150 million in added costs from tariffs this year, before accounting for mitigation efforts including price increases and supply-chain adjustments. Ingersoll was one of the few companies to lower its full-year earnings and organic sales guidance this earnings season. It did so primarily to reflect the economic uncertainty, rather than specific signs of weaker demand. That more conservative approach may provide the company more cushion should weakness in the consumer economy start to spill over into the industrial side, Melius Research analyst Rob Wertheimer wrote in a note. "Realistically none of us know what will happen," he said. "The present looks fine, and the future highly uncertain, no matter how companies guide." Deals, Activists and Corporate Governance | Dover Corp. agreed to buy Sikora AG, a German maker of precision measurement and inspection tools used in the production of wires and cables for data centers. The purchase price is €550 million ($622 million), or about 5.5 times what Sikora generated in revenue last year. That’s a reasonable valuation for a fast-growing business that will increase Dover’s exposure to data center infrastructure and the push to electrify more parts of the economy. Dover has been shedding businesses, including a clamps and grips unit, a commercial cooking equipment arm and, most recently, its garbage truck division, to thin out its conglomerate sprawl, while separately expanding in higher-growth industries such as the energy transition and predictive maintenance. Dover expects the Sikora deal to close in the current quarter.

Ametek Inc. agreed to pay $920 million to acquire Faro Technologies Inc., a provider of 3D measurement tools including laser scanners. The purchase price of $44 a share works out to a roughly 40% premium to what Faro shares were trading for before news of Ametek’s offer. Ametek is a serial acquirer and uses deals to turbocharge its sales and profitability. The Faro deal is a “vintage Ametek acquisition” — a niche technology company with high margins but also opportunities for eliminating overhead costs, improving supply chain sourcing and selling products on a more global platform, RBC analyst Deane Dray wrote in a note.

TransDigm Group Inc. CEO Kevin Stein announced he will retire in September, handing over the reins to current Co-Chief Operating Officer Mike Lisman. TransDigm shares fell about 5.5% on the announcement, a testament to investors’ affinity for Stein after a more than five-fold total return under his stewardship. But Lisman is familiar with TransDigm’s culture, having joined about a decade ago and holding various roles across the company including chief financial officer and head of its M&A effort, Melius Research analyst Scott Mikus wrote in a note. TransDigm was in the running to acquire Boeing’s Jeppesen navigation unit, Bloomberg News has reported. Private equity firm Thoma Bravo ultimately agreed to acquire that business, along with other Boeing digital assets, for $10.6 billion. “Although Jeppesen is a high-quality asset, investors should take comfort in the fact that TransDigm remained disciplined throughout the process,” Mikus said. The company has about $7 billion that it could deploy on acquisitions or share repurchases this year, he said. |